Hopper dryer

What is a hopper dryer:

Hopper dryer is also known as: Hot air dryer, plastic pellet dryer, plastic processing and drying equipment.

Hopper dryer is also known as: Hot air dryer, plastic pellet dryer, plastic processing and drying equipment.The hopper dryer blows constant high temperature wind into the drying cylinder through a drying fan. The setting parameters also vary with the drying time and temperature of different plastic materials. The size of the air inlet can be adjusted according to the required air volume, so that after the raw materials are dried and baked quickly, the original moisture of the raw materials in the barrel is taken away, and the original moisture of the raw materials in the barrel is taken away to achieve the removal of the moisture content of the raw materials. purpose. . The wind blown by the fan becomes high temperature dry hot air after being heated by electricity. The hot air can be evenly dispersed in the drying barrel through the screen protector and the perforated screen. Optional hot air recovery device, the blown air enters the drying fan after being filtered by the return air, forming a closed loop loop, saving electricity.

The hopper dryer is a replacement product of the standard hot air dryer. Based on the original function, environmental protection factors have been fully considered and improved. It can dry raw materials that are wet due to packaging, shipping or recycling.

The hopper dryer can be moved according to production requirements, and it is convenient to move when in use.

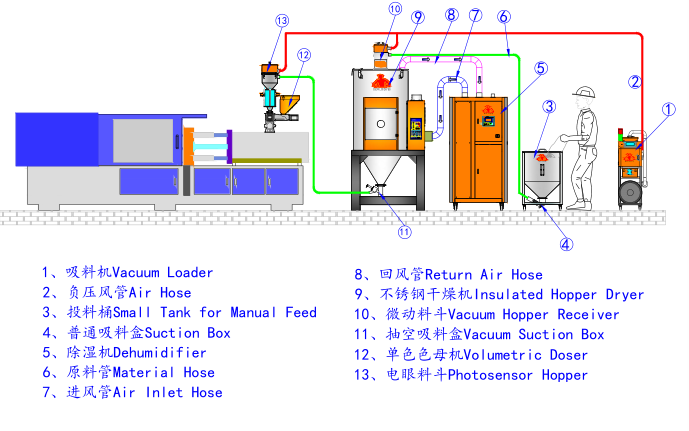

The hopper dryer can also be directly installed on the plastic molding machine to dry the materials, which is fast and saves space. All models can optionally be equipped with a 24-hour timer.

According to different hopper dryer manufacturers and companies, the performance and related parameters of the hopper dryer are different; But the principle and application are similar!

Hopper dryer composition

The hopper dryer is composed of discharge base,magnetic frame,suction box,hot air recovery system,A-shaped tripod,L-shaped tripod,cut-off suction box and other accessories;

The hopper dryer is composed of discharge base,magnetic frame,suction box,hot air recovery system,A-shaped tripod,L-shaped tripod,cut-off suction box and other accessories;Include:1.a top cover; 2.a fixed buckle;3.a shell;4.a fixed piece;5.a base; 6.a discharge port; 7.a fixed column; 8.Parameter console; 9.a bellows; 10 ,Fixed post b;

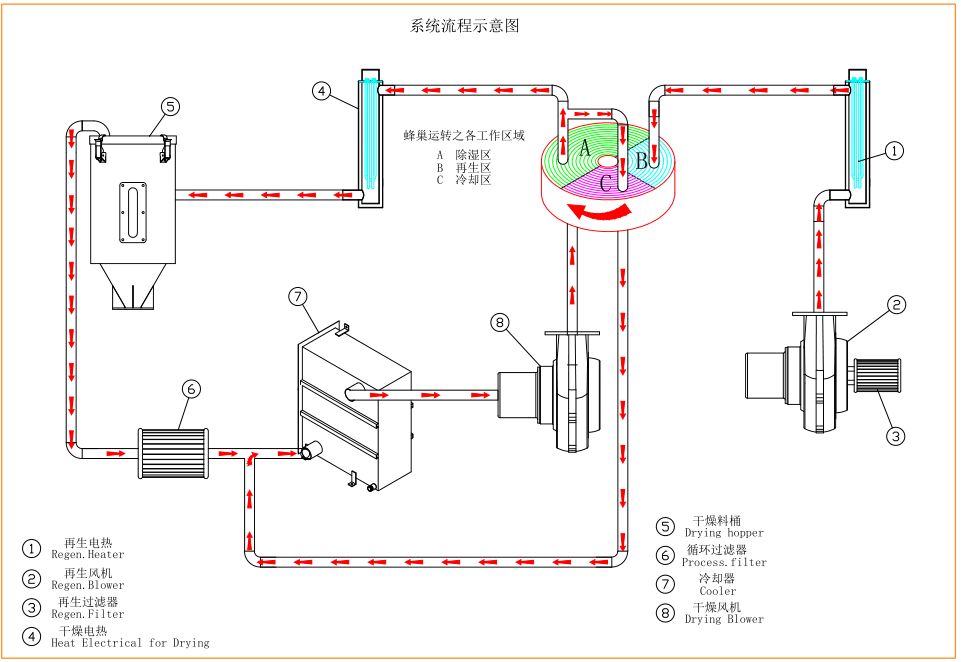

Working principle of hopper dryer:

In the raw material processing, the hopper dryer blows constant high temperature wind into the drying barrel through the drying fan. After the raw material is baked, the original moisture of the raw material in the barrel is taken away to achieve the purpose of removing the moisture in the raw material. The wind blown by the fan becomes high-temperature dry hot air after being heated by electric heating, and the hot air can be evenly dispersed in the drying barrel through the screen protector and the hole screen. Optional hot air recovery device, the blown air enters the drying fan after being filtered by the return air to form a closed circulation loop, saving electricity.

In the raw material processing, the hopper dryer blows constant high temperature wind into the drying barrel through the drying fan. After the raw material is baked, the original moisture of the raw material in the barrel is taken away to achieve the purpose of removing the moisture in the raw material. The wind blown by the fan becomes high-temperature dry hot air after being heated by electric heating, and the hot air can be evenly dispersed in the drying barrel through the screen protector and the hole screen. Optional hot air recovery device, the blown air enters the drying fan after being filtered by the return air to form a closed circulation loop, saving electricity.

Hopper dryer application

The hopper dryer is the most effective and economical model for drying plastic raw materials. It can dry raw materials that are wet due to, packaging, transportation or recycling. The direct-type design is particularly suitable for being directly installed on the plastic molding machine for drying, which is fast and space-saving. This up-blowing hot-air dryer can provide a loading capacity of 12~1000 kg, which is divided into thirteen types.

The hopper dryer is the most effective and economical model for drying plastic raw materials. It can dry raw materials that are wet due to, packaging, transportation or recycling. The direct-type design is particularly suitable for being directly installed on the plastic molding machine for drying, which is fast and space-saving. This up-blowing hot-air dryer can provide a loading capacity of 12~1000 kg, which is divided into thirteen types.The following is the parameter table of the hopper hot air dryer

| Hopper drying fan type | Flange diameter(mm) | Voltage(V) | power(W) |

| 12kg hopper dryer fan | 100mm | AC220V/AC380V | 75W |

| 25kg hopper dryer fan | 120mm | AC220V/AC380V | 135W |

| 50kg hopper dryer fan | 143mm/120mm | AC220V/AC380V | 155W/170W |

| 75kg hopper dryer fan | 140mm/150mm | AC220V/AC380V | 210W |

| 100kg hopper dryer fan | 140mm/150mm | AC220V/AC380V | 215W |

| 200kg hopper dryer fan | 150mm/170mm/190mm | AC380V | 320W |

| 400kg hopper dryer fan | 190mm/220mm | AC380V | 340W |

The following is a plastic dryer that is stronger than the hopper drying

Because the material and humidity that the hopper dryer can dry are different from the fan, the set parameters and the drying capacity per hour are also different!

Hopper dryer feature

1. Adopt high-performance hot air diffusion device that evenly disperses hot air to keep the plastic drying temperature uniform and increase drying efficiency.2. The special hot air elbow design can avoid the accumulation of dust on the bottom of the electric heating tube and cause burning.

3. The inside and internal parts of the barrel are all made of stainless steel.

4. The material barrel is separated from the bottom, easy to clean and quick to change materials.

5. The proportional deviation indicating temperature controller is used to accurately control the temperature.

6. There are double overheating protection devices, which can reduce accidents caused by man-made or mechanical failures.

7. Various models can provide preheating timing device, microcomputer control, and double-layer insulation material barrel selection.

8. All-digital P.I.D control LED status display.

9, 0-99 hours timed automatic startup.

10. Provide intermittent drying method to save electricity. (8-10 only use SHD-DT series)

11. Transparent window magnet base.

Drying hopper installation and use method

1. Installation: After drilling the base of the dryer, stand it upright on the inlet of the injection molding machine and fix it with fastening screws.2. Connect the power supply: turn on the distribution box and connect to the power supply referring to the wiring diagram. Pay attention to whether the power supply voltage is consistent with the local area, whether the specifications of the power switch and the load protection rating are appropriate, and start the fan to see whether the direction of rotation is consistent with the fan's mark In the same direction, connect a wire to the bolt with the "┷" grounding mark on the back of the electrical box and properly ground it.

3. Temperature adjustment: Refer to the drying temperature reference table of plastic raw materials, and set the temperature of the thermostat based on actual experience.

4. Air volume adjustment: Generally, it is fully open. If there is not much material in the tank or when a higher temperature is required, the air volume can be adjusted as appropriate, otherwise the expected drying effect will not be achieved.

5. Raw material packing: The packing should ensure that the internal material content is not less than 70%, but not too full, so as not to press the lid of the barrel and affect the drying effect.

6. Drying of transparent raw materials: The drying of transparent raw materials must be equipped with an air filter (original sponge, etc.) at the air inlet to prevent dust in the air from entering.

7. Preheating the barrel: Before putting the raw materials, the barrel is heated to dry the internal moisture. The preheating time is 10-20 minutes.

Maintenance and maintenance of hopper dryer

1. Clean the filter. The air inlet filter should be checked frequently and cleaned regularly. When the filter is blocked, the air intake will be reduced, which will affect the drying effect.2. Separator cleaning: when replacing raw materials, the separator should be wiped and cleaned.

3. Cleaning of the dust collection chamber: During the drying process, the powder material falls into the dust collection chamber for a long time to accumulate, so it needs to be cleaned regularly. The drying chamber can be opened and the fan can be turned on to blow the powder out by wind.

4. Cleaning up the agglomeration of raw materials on the shield: If for some reason, the raw material is agglomerated on the shield with excessively high temperature, the raw materials cannot fall. At this time, it is forbidden to scrape with hard objects such as iron rods to prevent the shield separator from being damaged. If it is damaged, the material barrel should be disassembled and taken out.

5. Shut down: After turning on and off the electric heater, turn off the fan in parallel to ensure that the heating cylinder is fully cooled to extend its life.

Precautions for operation of hopper dryer

(1) Ensure that the hot air is clean.(2) Measures should be taken to prevent coke dust and avoid backflow of hot air.

(3) For viscous materials, measures should be taken to minimize wall sticking.

(4) The exhaust air temperature is not allowed to exceed the requirements to ensure product quality and safety.

(5) During the drying process of the material, all parts of the equipment in contact with the material must be easy to clean and sterilize.

(6) In order to improve the solubility, instant solubility, and dry products, they should be continuously discharged from the drying chamber quickly and packaged after cooling.

Common faults and troubleshooting methods of hopper dryers

1. The fan of the hopper dryer does not rotateCauses:

①Poor contact of the fan power switch

②Poor contact of the AC converter for the fan

Elimination methods:

①Repair/replace the fan switch

②Repair/replace the AC contactor

2. The direction of the fan of the hopper dryer is different from the direction of the arrow (380V)

Cause:

①The direction of the fan wiring is reversed

Elimination method:

①Replace any 2 fan wires

3.Hot air pipe of hopper dryer smokes

Causes:

①The fan is damaged

②The temperature controller is out of control, extremely high temperature

Reasons eliminated:

①Replace the fan

②Check/repair whether the thermostat is out of control

4. The fan of the hopper dryer is rotating but there is no temperature

Causes:

①Electric heating switch failure

②AC contact failure

③Heating tube failure

④The thermostat is damaged

⑤The over-temperature protection tripping

Elimination method:

①Replace the switch

②Replace the AC

③Replace the heating tube

④Replace the over-temperature protector

⑤After the temperature drops, it will automatically recover

5. The fan of the hopper dryer is rotating but the temperature is not enough

Causes:

①Bad electric heating tube

②Trip of the over-temperature protector

③Lack of phase in electric power

Elimination method:

①check the electric heating tube

②automatically restore after the temperature drops

③check whether the phase is missing

④replace the thermostat

⑤replace the thermocouple

6.The fan of the hopper dryer is running but the temperature is extremely high

Cause:

①The thermocouple is broken

②The temperature controller is faulty。

163.com

163.com