|

Dongguan Hengju Machinery Equipment Co., Ltd.

World famous brand plastic pellet dryer equipment manufacturer |

|

High-tech enterprises

What is a plastic pellet dryer  Plastic pellet dryer: also known as plastic dryer, hopper dryer, plastic hot air dryer, plastic pellet dehumidifier, plastic dehumidification dryer, is a mechanical equipment that uses heat to reduce the moisture of plastic raw materials and is used to dry plastic pellets. The dryer evaporates and escapes the moisture in the material (usually refers to moisture or other volatile liquid components) by heating, and obtains a solid material with a specified moisture content; a constant high temperature wind is blown into the drying barrel by a drying fan to bake After the raw materials, the original moisture in the raw materials in the barrel is taken away to achieve the purpose of removing the moisture in the raw materials. The wind blown by the fan becomes high-temperature dry hot air after being heated by electric heating, and the hot air can be evenly dispersed in the drying barrel through the screen protector and the hole screen. Optional hot air recovery device, the blown air enters the drying fan after being filtered by the return air to form a closed circulation loop, saving electricity.

Plastic pellet dryer: also known as plastic dryer, hopper dryer, plastic hot air dryer, plastic pellet dehumidifier, plastic dehumidification dryer, is a mechanical equipment that uses heat to reduce the moisture of plastic raw materials and is used to dry plastic pellets. The dryer evaporates and escapes the moisture in the material (usually refers to moisture or other volatile liquid components) by heating, and obtains a solid material with a specified moisture content; a constant high temperature wind is blown into the drying barrel by a drying fan to bake After the raw materials, the original moisture in the raw materials in the barrel is taken away to achieve the purpose of removing the moisture in the raw materials. The wind blown by the fan becomes high-temperature dry hot air after being heated by electric heating, and the hot air can be evenly dispersed in the drying barrel through the screen protector and the hole screen. Optional hot air recovery device, the blown air enters the drying fan after being filtered by the return air to form a closed circulation loop, saving electricity.Especially in the medical and environmental protection industries, the machinery will fully adopt food stainless steel materials and fully enclosed feeding and discharging to avoid external pollution.

|

Composition of plastic pellet dryer: The plastic pellet dryer includes 1. a top cover; 2. a fixed buckle; 3. a shell; 4. a fixed piece; 5. a base; 6. a discharge port; 7. a fixed column; 8. Parameter console; 9. a bellows; 10 , Fixed post b; 11. fixed ball; 12, brim; 13, fixed ring; 14, fixed groove; 15, limit chute; 16, limit seat; 17, limit plate; 18, threaded hole; 19, Fixed spring; 20, limit bolt. ;Schematic diagram of plastic pellet dryer 1.Top cover; 2. Fixing buckle; 3. Shell; 4. Fixing piece; 5. Base; 6. Discharge port; 7. Fixing column a; 8. Parameter console; 9. Bellows; 10. Fixed column b;

1.Top cover; 2. Fixing buckle; 3. Shell; 4. Fixing piece; 5. Base; 6. Discharge port; 7. Fixing column a; 8. Parameter console; 9. Bellows; 10. Fixed column b;Drying drum, fan and plastic particle collection drum. The air outlet of the fan is connected to the drying cylinder through a pipe. The heater is installed in the pipeline. The air outlet of the drying cylinder is connected to the air inlet of the plastic particle collection cylinder. The air outlet of the plastic particle collecting cylinder is connected with the air inlet of the fan, and a particle filtering device is arranged in the drying cylinder. There is a stirrer in the drying cylinder; The air inlet of the fan is equipped with a filter; The heater is equipped with an overheat protection device; The fan has an air inlet for supplementary air; The drying cylinder is provided with an insulating layer.

| Working principle of plastic pellet dryer: How plastic pellet dryer works Working principle and use process: Before using the plastic dryer, you should check it first, and it can be used after the check is correct. First, install and fix the shell, and align the bottom of the shell with the position of the base ,so that the fixed ball is aligned with the limit. At the position of the chute, then slowly slide the shell to the bottom end so that the fixed ball fits tightly with the limit chute, and then slide the shell according to the route of the fixed ball and the limit chute, so that the fixed ball 11 slides to The highest point of the limit chute makes the fixing groove and the fixing ring closely fit, then the base and the shell can be clamped and fixed from the inside, and then align the bolts at the position of the fixing piece, and rotate the bolts so that the bolts will pass through the threads. The base and the shell are limited and fixed from the outside, and the disassembly is also very simple. You only need to rotate the bolts in reverse, so that the bolts and the fixing piece are separated by screw rotation, so that the base and the shell are separated from the outside, and then the shell is in accordance with the track of the limit chute Sliding separates the fixed ball from the limit chute, and then slides the shell to the top to separate the fixed ring from the fixed groove. Not only is it easy to use and convenient, but it is also quick and convenient to install and disassemble, which effectively reduces the difficulty of work and ensures normal work. Progress, increase work efficiency, and then install and fix the operation cabinet, align the limit seat on one side of the operation cabinet with the position of the fixed column, and then pull the limit plate 17, so that the fixed spring 19 is contracted, and then the operation cabinet 8 Slowly slide down, so that the bottom end of the limit seat is engaged with the fixed column, the fixed spring loses its force, and the limit plate bounces back to the side of the fixed column, thereby exerting a force on the fixed column, thereby The operation cabinet is fixed, and then the limit bolts are rotated, so that the limit bolts are fixed to the fixed posts and threaded holes through the rotating threads, thereby double-fixing the operation cabinet, which is not only simple and convenient to use, but also has high stability and effective installation of the operation cabinet , Reduce the difficulty of installation and disassembly of the operation cabinet, facilitate the detection and maintenance of the operation cabinet, and increase the work efficiency and economic benefits. Working principle and use process: Before using the plastic dryer, you should check it first, and it can be used after the check is correct. First, install and fix the shell, and align the bottom of the shell with the position of the base ,so that the fixed ball is aligned with the limit. At the position of the chute, then slowly slide the shell to the bottom end so that the fixed ball fits tightly with the limit chute, and then slide the shell according to the route of the fixed ball and the limit chute, so that the fixed ball 11 slides to The highest point of the limit chute makes the fixing groove and the fixing ring closely fit, then the base and the shell can be clamped and fixed from the inside, and then align the bolts at the position of the fixing piece, and rotate the bolts so that the bolts will pass through the threads. The base and the shell are limited and fixed from the outside, and the disassembly is also very simple. You only need to rotate the bolts in reverse, so that the bolts and the fixing piece are separated by screw rotation, so that the base and the shell are separated from the outside, and then the shell is in accordance with the track of the limit chute Sliding separates the fixed ball from the limit chute, and then slides the shell to the top to separate the fixed ring from the fixed groove. Not only is it easy to use and convenient, but it is also quick and convenient to install and disassemble, which effectively reduces the difficulty of work and ensures normal work. Progress, increase work efficiency, and then install and fix the operation cabinet, align the limit seat on one side of the operation cabinet with the position of the fixed column, and then pull the limit plate 17, so that the fixed spring 19 is contracted, and then the operation cabinet 8 Slowly slide down, so that the bottom end of the limit seat is engaged with the fixed column, the fixed spring loses its force, and the limit plate bounces back to the side of the fixed column, thereby exerting a force on the fixed column, thereby The operation cabinet is fixed, and then the limit bolts are rotated, so that the limit bolts are fixed to the fixed posts and threaded holes through the rotating threads, thereby double-fixing the operation cabinet, which is not only simple and convenient to use, but also has high stability and effective installation of the operation cabinet , Reduce the difficulty of installation and disassembly of the operation cabinet, facilitate the detection and maintenance of the operation cabinet, and increase the work efficiency and economic benefits.The plastic granule dryer includes a drying cylinder, a fan and a plastic granule collecting cylinder. The air outlet of the fan is connected to the drying cylinder through the duct The surface of the tube is provided with a heating device. The heater and the heater are provided with overheating protection devices. The air outlet of the drying cylinder is connected to the air inlet of the plastic particle collection cylinder, and the air outlet of the plastic particle collection cylinder is connected to the air inlet of the fan. The dryer has a filter, and the filter screen and the fan have auxiliary air inlets. The exhaust port of the drying cylinder is equipped with a plastic particle filter. If it is a larger drying box, it can be equipped with a stirrer. An insulating layer is provided on the outer surface of the drying cylinder. Features of plastic pellet dryer: 1. The raw material contact surface is made of all stainless material.2. Precision die-casting aluminum shell, smooth surface, good heat preservation performance. 3. Silent fan, optional air filter to ensure the cleanliness of raw materials. 4. Both the barrel body and the machine base are equipped with viewing windows, which can directly observe the internal raw materials. 5. The curved design of the electric heating cylinder avoids burning caused by the accumulation of raw material powder at the bottom of the cylinder. 6. The proportional deviation indicating temperature controller is used to accurately control the temperature. 7. Can be customized: double-layer material barrel, stainless steel electric heating tube, heat-dissipating electric heating tube, high temperature fan. The cast aluminum mold is independently designed, the barrel body is turned backwards, and it is suitable for any manipulator. The stainless steel upper and lower screens have a smooth, smooth surface and easy to clean. 8. It is widely applicable to the drying of any plastic raw materials, and can dry materials of different materials and colors at the same time. It is especially suitable for drying materials that require high temperature accuracy, low dosage, and many colors. It is also suitable for preheating or drying in food, pharmaceutical, electronics, electroplating and other industries. 9. Using PI temperature control to accurately control the drying temperature. 10. It integrates temperature and time control to facilitate the setting of drying parameters for various materials. 11. High-quality protective materials and high-sealing design avoid unnecessary energy loss. 12. Adjustable air inlet. 13. Motor overload protection, phase sequence protection.

| Model and parameters of plastic pellet dryer:

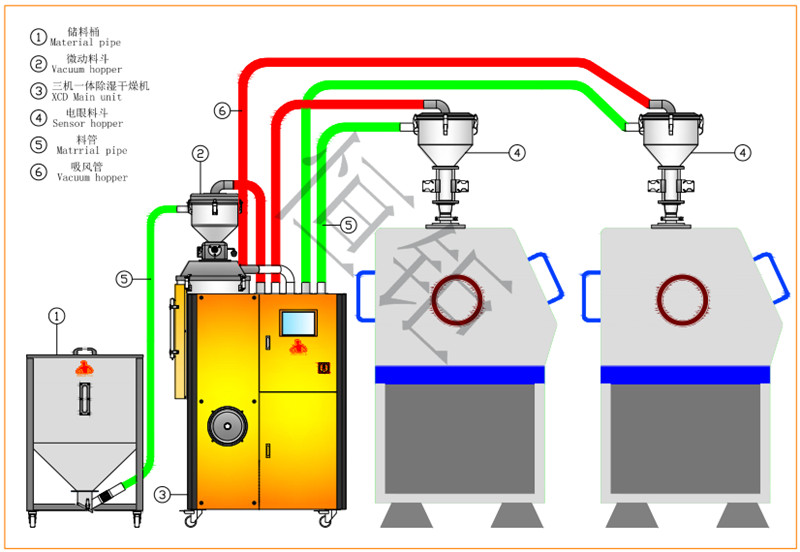

Application and design scheme of plastic pellet dryer: The plastic pellet dryer is suitable for mixing powder or granular materials in chemical, food, pharmaceutical, feed, ceramics, metallurgy and other industries.Application of Plastic Granule Dryer in Central Conveying System The plastic pellet dryer is an important part of the central feeding system. It can automatically dehumidify and automatically dry the moisture in the plastic particles (for example: PC, PE particles, PET particles, PLA, PP and other plastic particles) during the production process; solve the product problems such as bubbles and cracks in the production process. Moreover, the plastic pellet dryer is integrated into the central feeding system, which will all realize the unified control of the plastic pellet dryer by the host console, and will fully realize automatic production!

The plastic pellet dryer is an important part of the central feeding system. It can automatically dehumidify and automatically dry the moisture in the plastic particles (for example: PC, PE particles, PET particles, PLA, PP and other plastic particles) during the production process; solve the product problems such as bubbles and cracks in the production process. Moreover, the plastic pellet dryer is integrated into the central feeding system, which will all realize the unified control of the plastic pellet dryer by the host console, and will fully realize automatic production!This is a three-in-one plastic granule dryer with fully automatic suction, dehumidification and drying, which is energy-saving and space-saving.

| Application of plastic pellet dryer Ceramic Enterprise Use the hopper dryer to install directly on the injection molding machine. It is very important to completely dry to a moisture content of less than 0.1%, otherwise the injection molded product will be white (white aerosol), yellow, foam, silver, fragile, unsightly, poor mechanical properties and large loss of raw material for plastic particles.

Use the hopper dryer to install directly on the injection molding machine. It is very important to completely dry to a moisture content of less than 0.1%, otherwise the injection molded product will be white (white aerosol), yellow, foam, silver, fragile, unsightly, poor mechanical properties and large loss of raw material for plastic particles.Injection molding process 1. Drying: (1) platic pellet dryer below 90~110℃. Dry for 2~4 hours (The dryer must be installed on the injection molding machine) (2) Oven below 100~110℃. Dry for 3~6 hours 2. Inject abrasive 3. Cool and shape Technical Parameters Cylinder temperature: feed section: 230~240℃; middle section: 235~245℃; discharge section: 245~250℃; nozzle: 250~260℃; mold temperature: 60~100℃ Injection pressure: 80~110mpa Molding cycle: 20~25s Screw speed: 30~60 r/min.

| Application of plastic pellet dryer in injection molding industry Commonly used plastic insulation materials for wires and cables are: polyethylene [low density (LDPE), medium density (HDPE), high density (HDPE), linear low density (LLDPE)], polyvinyl chloride (PVC), cross-linked polyethylene [ Peroxide cross-linking material, silane cross-linking material, radiation cross-linking material] (XLPE), cross-linked polyvinyl chloride (XLPVC), low-smoke halogen-free polyolefin (DWPJ), low-smoke low-halogen polyolefin (DDPJ) , Polypropylene (PP), polytetrafluoroethylene (PTFE/F-4), polyperfluoroethylene propylene (FEP/F-46), polyamide (PA6), polyimide (PI), etc.;.

Commonly used plastic insulation materials for wires and cables are: polyethylene [low density (LDPE), medium density (HDPE), high density (HDPE), linear low density (LLDPE)], polyvinyl chloride (PVC), cross-linked polyethylene [ Peroxide cross-linking material, silane cross-linking material, radiation cross-linking material] (XLPE), cross-linked polyvinyl chloride (XLPVC), low-smoke halogen-free polyolefin (DWPJ), low-smoke low-halogen polyolefin (DDPJ) , Polypropylene (PP), polytetrafluoroethylene (PTFE/F-4), polyperfluoroethylene propylene (FEP/F-46), polyamide (PA6), polyimide (PI), etc.;.

| Application of plastic pellet dryer in extrusion industry Dehumidification and drying are used for automobile plastic parts. The most used plastic in automobiles is PP and modified materials, followed by ABS, PMMA, PC, POM, PVC, etc.

Dehumidification and drying are used for automobile plastic parts. The most used plastic in automobiles is PP and modified materials, followed by ABS, PMMA, PC, POM, PVC, etc.Plastics used in the medical industry Polyvinyl chloride (PVC, Polyvinyl chloride) Polyethylene (PE, Polyethylene) PP (polypropylene) Polystyrene (PS) and K resin ABS, Acrylonitrile Butadiene Styrene copolymers Polycarbonate (PC, Polycarbonate) PTFE (Polytetrafluoro ethylene) The application of the plastic pellet dryer is closely related to the design plan, and the design plan is inseparable from the company's factory structure and raw materials, as well as the company's requirements! Only a reasonable understanding of the company's application of raw materials combined with the company's factory structure can design a good solution, a set of good design solutions to meet the company's production requirements, reasonable application space and cost savings.

| Operating instructions for plastic pellet dryer: plastic pellet dryer operation control panel 1. Set all the current disconnect switches in the control box to the "ON" position, press the run/stop button on the control panel, the indicator light is on to indicate the start of operation, press the run/stop button again after the drying is completed, the indicator light flashes slowly , Cooling operation, shutdown after 5 minutes of operation.

1. Set all the current disconnect switches in the control box to the "ON" position, press the run/stop button on the control panel, the indicator light is on to indicate the start of operation, press the run/stop button again after the drying is completed, the indicator light flashes slowly , Cooling operation, shutdown after 5 minutes of operation.2. Setting of drying temperature: Press the mode switch key twice according to the instruction, when the drying temperature setting display shows the unit symbol of °C, you can set the temperature to be dried by pressing "△". 3. The operation of conveying material can be divided into one-time, two-time and three-time conveying operation. Press the corresponding conveying operation/stop button and number of times according to different times. Example: Once the conveying material is running, press the conveying 1 run/stop key, and the indicator light flashes quickly at this time. When the conveying 1 run/stop button is pressed again, the indicator light slowly dims, when the indicator does not flash, it means Full barrel. The second and third conveying operations can be deduced by analogy. 4. When the plastic pellet dryer is automatically operated to feed materials from the drying cylinder to the hopper of the molding machine, first turn on the conveying 1 to keep the material in the drying cylinder full, and then press conveying 2 or 3 to feed the material from the drying cylinder to the hopper of the molding machine. When the material in the hopper is full, the sensor indicator light on the hopper is on, and the conveying 2 (conveying 3) indicator light is on at the same time. 5. If an abnormality occurs during the use of the plastic pellet dryer, the alarm will sound, and the abnormal code will be displayed on the monitor. Press the power button to confirm the alarm and the alarm will stop. When the abnormality is eliminated, the alarm code will be eliminated by pressing the reset button. 6. When the warning light flashes, please check whether the raw materials have been used up, or enter the system console panel to check whether there is a problem, and correct it in time. (Automatic error correction function) Precautions for plastic pellet dryer: Points for attention when using the plastic pellet dryer:1. The plastic pellet dryer should be cleaned frequently and kept clean. The dehumidifier should be placed in the center of the room. The air inlet and outlet of the refrigerated dryer should not be blocked by obstructions, and the air filter should be cleaned. When the ambient temperature is lower than 15℃, the water droplets attached to the evaporator surface will freeze and the dehumidifier effect will be weakened. If the ambient temperature exceeds 40℃, the pressure in the system will increase and the compressor will overload. At this time, the overload protector The circuit should be cut off, otherwise the compressor motor will be damaged. So the best temperature range for dehumidifier is 15℃~40℃. If the humidity in the air is below 30%, it will be too dry and uncomfortable, so a reliable humidity controller will control it to maintain the range of 50% to 60%. When in use, close doors and windows as much as possible to achieve dehumidification in the room. The body of the desiccant dryer must be placed flat, not tilted or turned sideways, to avoid machine failure or abnormal noise. 2. The water storage in the desiccant dryer is too full. In order to avoid overflowing and contaminating the ground, when the machine body must be moved during operation, please unplug the power cord first, and then pour out the water in the water storage bucket. After moving the dehumidifier, it is best to put it statically for four to six hours before starting to use it. Because the compressor pipeline in the dehumidifier contains cold coal, it must take four to six hours to return the cold coal to its original position after being moved. 3. Clean the air filter regularly (about once every two weeks) to maintain the dehumidification and dust removal efficiency and life of the machine. Clean the air filter and wash it with water below 40°C; it is better to clean it with detergent. After washing off the dust, rinse it with water, dry it in the shade and put it back into the body. When cleaning the body, wipe it gently with a damp cloth; avoid directly splashing water for cleaning, so as not to damage the electrical insulation. Adhesives on the surface of the body can be cleaned with soap and water. Avoid spraying with gasoline, petroleum spirit, solvent or spray insecticide to avoid peeling paint or discoloration. Do not use thin rods or iron wires to dig out the inside of the machine to avoid malfunction or danger. Please unplug the power cord to maintain the life of the machine when it is out of power, not used for a long time, or when traveling. Product alias:plastic pellet dryer, hopper dryer,hot air dryer,plastic dehumidifying dryer,Plastic pellet dehumidifier |