Gravimetric blender |

|

What is a gravimetric blender?  The gravimetric blender is to accurately mix various raw materials in proportion to obtain new and uniformly mixed raw materials required for production; it is mainly used in injection molding and extrusion industries.

The gravimetric blender is to accurately mix various raw materials in proportion to obtain new and uniformly mixed raw materials required for production; it is mainly used in injection molding and extrusion industries.The gravimetric blender is an automatic mechanical equipment integrating weighing, metering and mixing functions. Using PLC controller and advanced batching algorithm, it can automatically carry out weighing analysis, and measure and mix one, two, three, four, five, six or more kinds of particles or plastic powder raw materials according to the batching ratio. In order to obtain the new mixed raw materials required for production, the weighing and mixing accuracy can reach ±0.1% (even particles can be accurate to one particle unit). So as to solve the problems of manual weighing errors and uneven mixing in production, and improve product quality! Gravimetric batch blender type: Loss in weight gravimetric blender This type of gravimetric blender measures the "loss in weight" from two or more hoppers using a load cell under each hopper. Material is usually dispensed from the hoppers using a screw conveyor. All materials are dispensed together and the rate of dosing from each hopper is controlled to ensure the correct blend is achieved. Gain in weight gravimetric blender(sometimes called a batch blender) A gain in weight gravimetric blender has two or more hoppers arranged above a weigh-pan. These hoppers contain the components which are to be mixed, at the base of each hopper there is a valve to control the dispensing of material from the component hopper into the weigh-pan. The components are dispensed one at a time into the weigh pan until the target or batch weight is reached. Once the batch has been weighed out the contents of the weigh-pan are dispensed into a mixing chamber where they are blended. The resulting mixture exits the base of the mixing chamber into the processing machine. A typical application of a gravimetric blender would be mixing virgin plastic granules, recycled plastic, and masterbatch (an additive used to colour plastics) together. . |

| Energy-saving gravimetric blender | Sealed gravimetric blender | Simple gravimetric blender | |||||||

|

|

|

|||||||

| Price:4.5~150,000 | Price:4.5~150,000 | Price:4.5~150,000 | |||||||

| type:Loss in weight/Gain in weight | type:Loss in weight/Gain in weight | type:Loss in weight/Gain in weight | |||||||

| Suitable for plastics and extrusion industries; high precision, energy saving, fast and uniform mixing, mixing multiple raw materials at one time, durable, with a shelf life of up to 3 years | This is a closed loading and unloading gravimetric blender, which is mainly used for gravimetric blenders in environmental protection industries (food, medicine, ceramics, precision parts) that require high precision.. | This is a gravimetric blender that can be directly installed on the extruder of the injection molding machine, saving space, time, money, and electricity; the mixing speed is fast. | |||||||

| Standard gravimetric blender | Ordinary gravimetric blender | WSB/BD gravimetric blender | |||||||

|

|

|

|||||||

| Price:4.5~150,000 | Price:4.5~150,000 | Price:4.5~150,000 | |||||||

| type:Loss in weight/Gain in weight | type:Loss in weight/Gain in weight | type:Loss in weight/Gain in weight | |||||||

| This is a standard gravimetric blenders, mainly used for gravimetric blender that require electronic components and wire and cable industries. | This is an ordinary gravimetric blender, specially developed and designed for small and medium enterprises. It can be flexibly moved or fixed, and its functions will be designed according to the needs of the enterprise. | The WSB/BD batch gravimetric blender has a fast-acting sliding door, independent mixing chamber and touch screen interface. 4 different ways to enter the mixing formula, easy to clean design, maximize the efficiency of the machine. | |||||||

Comprehensive functions of gravimetric blender: Can mix 2~12 kinds of materials at the same time;Stir 50~3000kg of mixed raw materials simultaneously for the first hour;Using PLC control system, automatic alarm system, automatic error correction;can be moved, fixed or directly installed on the production equipment;Can store more than 100 combination ingredients;Use thick stainless steel or 304 (food grade) stainless steel;Energy saving per hour is based on equipment power, adopting a new generation of energy-saving technology;Various models adopt corresponding stirring rotors according to the requirements of raw materials. The mixing of micro-materials and micro-materials, particles and micro-materials determines the mixing function of the rotor gravimetric blender;Exportable history as text files with date and time stamps;Access to all features of blender to allow you to customize system to your process if required.;View material data, Access Recipe database, toggle Batch mode on and offline, Tag information and to increase throughput, operate in Fast mode;It is convenient to check the throughput, weight and distribution components of each batch, as well as the state of the mixed materials, and customize the mixing volume per hour;The shelf life is as long as 3-5 years. |

|||||||||

| Model | HGB-50 | 100 | 200 | 400 | 600 | 800 | 1200 | 2000 | 2500 | 3000 | ||||||||||||||||||||

| Qty of group number | 1-12 | |||||||||||||||||||||||||||||

| Mixing capacity(kg/hr) | 50 | 100 | 200 | 400 | 600 | 800 | 1200 | 2000 | 2500 | 3000 | ||||||||||||||||||||

| Batch weight(kg) | 0.6 | 1.2 | 2.2 | 4.5 | 6 | 8 | 12 | 20 | 25 | 30 | ||||||||||||||||||||

| Main material range(%) | 5-100 | |||||||||||||||||||||||||||||

| Additive mixing range(%) | 0.5-10 | |||||||||||||||||||||||||||||

| Main hopper volume(L) | 18 | 25 | 32 | 45 | 70 | 100 | 130 | 160 | 180 | 230 | ||||||||||||||||||||

| Mixing barrel volume(L) | 6 | 6 | 20 | 20 | 40 | 40 | 80 | 80 | 100 | 180 | ||||||||||||||||||||

| Power supply(v/hz) |

|

|||||||||||||||||||||||||||||

| Total power(kw) | 0.12 | 0.12 | 0.25 | 0.25 | 0.55 | 0.55 | 1.5 | 1.5 | 1.5 | 3 | ||||||||||||||||||||

| Compressed air(kgf/cm2) | 6-8 | |||||||||||||||||||||||||||||

| Max noise level(dB) | <75 | |||||||||||||||||||||||||||||

Operation and working principle of gravimetric blender

The gravimetric blender is based on PLC control and is an automated equipment that completes the uniform mixing of multiple or multiple raw materials. First, set the formula ratio of each ingredient on the touch screen console of the gravimetric blender. When various raw materials enter the upper hopper, there is a weighing platform below the hopper to weigh the raw materials, and then the weighing data is transmitted to the console. When the hopper raw material weighing count value is the same as the ratio set by the console, the hopper feeding system is closed, the valve at the bottom of the hopper automatically opens, all the hopper raw materials enter the mixing tank, and the mixing tank mixing system automatically opens; when all the raw materials enter the mixing tank . The valve at the bottom of the hopper is closed, and the feeding system at the top of the hopper is opened. According to the mixing system time set by the console, the weighed various raw materials are fully stirred in the mixing tank. When the mixing system reaches the time set by the console, the mixing is completed, the valve at the bottom of the mixing tank is automatically opened, the mixed raw materials are automatically output, and the next production cycle is entered! Gravimetric blender operation:

Gravimetric blender operation: 1. First plug in the power, then turn on the switch, the machine will start.

1. First plug in the power, then turn on the switch, the machine will start.2. If the discharge port is not in the desired position, you must gently push the gravity agitator until the discharge port stops at the desired position.

3. Before starting the machine, please check whether the electrical equipment is normal and whether the mixing cylinder cover is tightly closed.

4. After starting the machine, check the equipment console to see if there is any abnormality, you can use the automatic error correction function,

5. Proportioning design parameters for each hopper raw material, (Figure 1, 2, 3, 4, 5, 6)

6. Design parameters for the feed rate of raw materials in each hopper,

7. Carry out the design parameters for the mixing time.

8. Design parameters for the discharging speed of the stirred mixture.

9. The controller is equipped with a standard USB2.0 interface, which can save the mixing ratio data to the U disk, which is convenient for production quality control.

10. Volume mixing measurement method increases the amount of ingredients; with formula storage function, it can store more than 100 groups of formulas at most. Function of hierarchical security code control and alarm history record.

11. When the warning light flashes, please check whether the raw materials have been used up, or enter the system console panel to check whether there is a problem, and correct it in time. (Automatic error correction function)

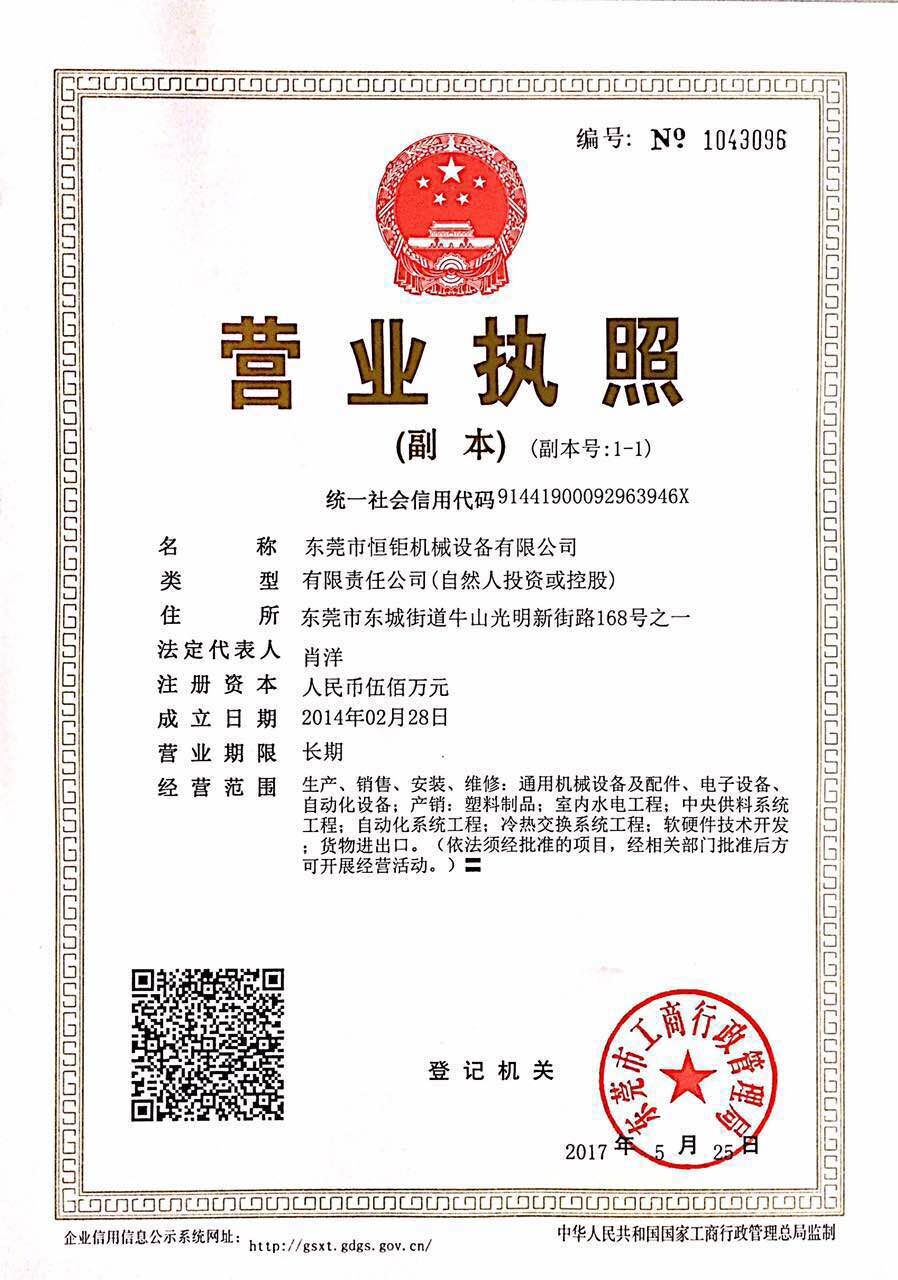

Company Profile

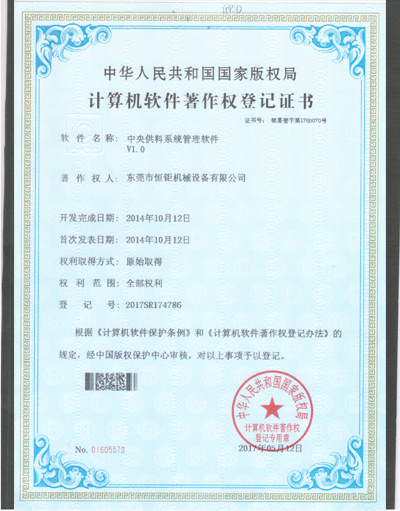

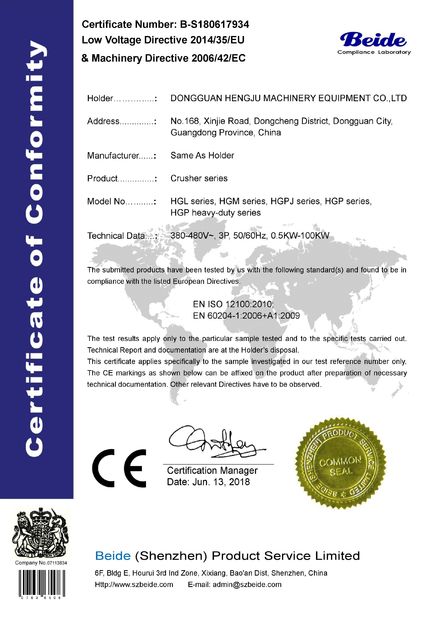

We are a professional entity gravimetric blender manufacturer company. We have developed weighing and mixing technology for nearly ten years. We are also pioneers in gravimetric blender. The company covers an area of more than 5,000 square meters, has more than 10 experienced technical development teams, a number of gravimetric blender technology patents and gravimetric blender software patents, and its products are sold to 132 countries and regions (America,Englandm, India, Vietnam, Cambodia, Laos, Thailand, Myanmar, Philippines, Malaysia, Singapore, Indonesia, etc.), has many agents all over the world, and supports all aspects of strategic cooperation among agents!

We are a professional entity gravimetric blender manufacturer company. We have developed weighing and mixing technology for nearly ten years. We are also pioneers in gravimetric blender. The company covers an area of more than 5,000 square meters, has more than 10 experienced technical development teams, a number of gravimetric blender technology patents and gravimetric blender software patents, and its products are sold to 132 countries and regions (America,Englandm, India, Vietnam, Cambodia, Laos, Thailand, Myanmar, Philippines, Malaysia, Singapore, Indonesia, etc.), has many agents all over the world, and supports all aspects of strategic cooperation among agents!Enterprise Qualification Certificate:

| Enterprise production certificate | Software copyright certificate for gravimetric blender | Gravimetric blender patent certificate | High-tech certificate | Export quality certification |

|

|

|

|

|

Composition and accessories of Gravimetric blender

Composition of gravimetric blender:The gravimetric blender consists of 1. Upper hopper, 2. Display, 3. Unloading cylinder, 4. Controller, 5. Mixing box, 6. Observation window, 7. Lowering cylinder, 8. Discharge valve, 9. Sub-hopper, 10. Motor, 11. Feeding port of sub-hopper, 12. Feeding port of sub-hopper, 13. Pull plate, 14. Cylinder assembly box, 15. Weighing hopper, 16. Horizontal screw, 17. Mixing hopper and other accessories combined to make.

Main accessories of gravimetric blender:

| Upper hopper | Screw Weight Loss Scale | touch screen console | Stirring and mixing system |

|

|

|

|

| Bracket | Micro-motion hopper | Weighing hopper | circuit system |

|

|

|

|

|

Application and design scheme of Gravimetric blender: The gravimetric blender is suitable for mixing powder or granular materials in chemical, food, pharmaceutical, feed, ceramics, metallurgy and other industries.

| Application of gravimetric blender in plastic granule Input each color masterbatch into each hopper on the top of the weighing mixer, set the parameters in the console (control panel), and weigh and measure each color masterbatch to be accurate to the particle size and set the mixing time. Stirring is carried out, and then the materials are automatically output, and the weighing and mixing are completed. Will be automatically entered into another production device! These weighing, batching and mixing tasks will be completed automatically, calculated automatically by the computer, with an accuracy value of 0.01% or particles

Input each color masterbatch into each hopper on the top of the weighing mixer, set the parameters in the console (control panel), and weigh and measure each color masterbatch to be accurate to the particle size and set the mixing time. Stirring is carried out, and then the materials are automatically output, and the weighing and mixing are completed. Will be automatically entered into another production device! These weighing, batching and mixing tasks will be completed automatically, calculated automatically by the computer, with an accuracy value of 0.01% or particlesApplication of gravimetric blender Ceramic Enterprise |  Application of gravimetric blender in ceramic industry. The main raw materials of ceramics are powder and granules. We use multiple hoppers, powder gauges and particle gauges to better solve the batching problem. When mixing, we use a special mixing barrel to mix the agglomerated powder evenly with the particles. The mixing barrel mixes the powder and the particles together to make the ratio and mixing more uniform; due to the large amount of powder used There may be four types of raw materials and powders in the workshop. We will use the separation method of Gravimetric blender and workshop, and adopt pipeline transportation to ensure that the workshop and equipment are not polluted by powder, while extending the service life of the Gravimetric blender and the environmental protection of the workshop ,product quality.

Application of gravimetric blender in ceramic industry. The main raw materials of ceramics are powder and granules. We use multiple hoppers, powder gauges and particle gauges to better solve the batching problem. When mixing, we use a special mixing barrel to mix the agglomerated powder evenly with the particles. The mixing barrel mixes the powder and the particles together to make the ratio and mixing more uniform; due to the large amount of powder used There may be four types of raw materials and powders in the workshop. We will use the separation method of Gravimetric blender and workshop, and adopt pipeline transportation to ensure that the workshop and equipment are not polluted by powder, while extending the service life of the Gravimetric blender and the environmental protection of the workshop ,product quality.Application of gravimetric blender in injection molding industry |  Application of Gravimetric blender in injection molding industry. The main plastic powders and granules in the injection molding industry. We use multiple hoppers, powder meter or particle meter to better solve the batching problem. When mixing, we use a special mixing barrel to mix plastic particles or plastic powder. The mixing barrel mixes the powder or granules together to make the ratio and mixing more uniform. The corresponding sealing system is formulated to ensure that the workshop and equipment are not polluted by dust, and at the same time extend the service life of the Gravimetric blender and the environmental protection and product quality of the workshop.

Application of Gravimetric blender in injection molding industry. The main plastic powders and granules in the injection molding industry. We use multiple hoppers, powder meter or particle meter to better solve the batching problem. When mixing, we use a special mixing barrel to mix plastic particles or plastic powder. The mixing barrel mixes the powder or granules together to make the ratio and mixing more uniform. The corresponding sealing system is formulated to ensure that the workshop and equipment are not polluted by dust, and at the same time extend the service life of the Gravimetric blender and the environmental protection and product quality of the workshop.

| Application of gravimetric blender in extrusion industry Application of gravimetric blender in extrusion industry. The main plastic powder and granule in the extrusion industry. In the production workshop of the enterprise, we use more reasonable equipment installation and equipment connection, and adopt "Internet of Things" and "4.0 Industry" design solutions to save costs and save factory space. We use multiple hoppers, powder meters or granules in one machine. The instrument can better solve the problem of uniform ingredients. A multi-distribution sealed distribution method is adopted to ensure that the workshop and equipment are not contaminated by dust, and at the same time extend the service life of the weighing mixer and the environmental protection and product quality of the workshop.

Application of gravimetric blender in extrusion industry. The main plastic powder and granule in the extrusion industry. In the production workshop of the enterprise, we use more reasonable equipment installation and equipment connection, and adopt "Internet of Things" and "4.0 Industry" design solutions to save costs and save factory space. We use multiple hoppers, powder meters or granules in one machine. The instrument can better solve the problem of uniform ingredients. A multi-distribution sealed distribution method is adopted to ensure that the workshop and equipment are not contaminated by dust, and at the same time extend the service life of the weighing mixer and the environmental protection and product quality of the workshop.

|

Gravimetric blender technology and installation solutionsHow to let the gravimetric blender solve the problem for the enterprise is the key. Energy saving, environmental protection, time saving, automation and intelligence, the installation of gravimetric blenders for enterprises will bring long-term value to enterprises. This is why we have been developing gravimetric mixers and gravimetric mixers. Therefore, we tested many ways to change this technology. For example, according to the different raw materials, we will use a gravimetric blender for weight reduction, weighing, liquid and other measurement methods. The mixing is also based on the testing of various raw materials; in the mixing screw and double blades, the mixing is more uniform, and the particles and micro particles are evenly mixed, and the density characteristics of the raw materials are used to formulate corresponding technical solutions! We have our own R&D capabilities, manufacturers and developers, and have patents for gravimetric blenders and software program certificates.Thousands of successful cases, including Toyota, Honda, Foxconn and other well-known companies, only technology + installation can better formulate corresponding solutions, so we also have higher technical requirements for installation to save company funds and company space ,In production, this is a gravimetric blender, which can mix multiple raw materials, and automatically provide the blended raw materials to multiple machines at the same time according to the company's needs. This requires a good solution to complete. For example, factory size and production materials. Only through the displacement, conveying distance, energy consumption and other related data of the machine, we can provide the corresponding gravity model and installation rule design of the gravity mixer, so as to reasonably save more funds and space occupied. And provide the company with better solutions to save money, save company space, energy saving, environmental protection, time saving, labor saving, automation, intelligence and solutions with long-term value. [More gravimetric blender information] |

+8613669807274

+8613669807274